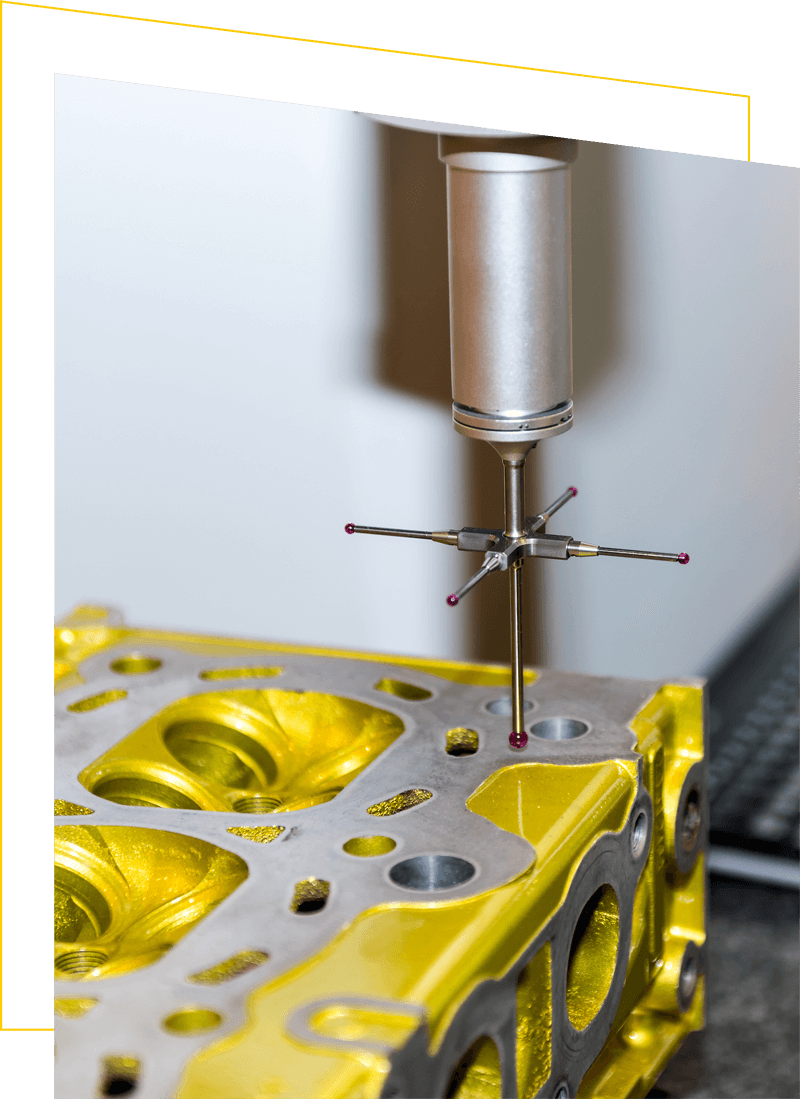

Full 5 axis CMM.

All our parts are planned for the manufacture process to include stage and final inspection operations. This ensures control of product conformity throughout the manufacturing process inline with customer requirements. We operate a fully automated CMM with PC-DMIS CAD control. PC-DMIS CAD can extract part data directly from a model; eliminating mistakes when inspecting and evaluating complex parts and ensuring conformity to customer requirements.

Added inspection resource.

We also have 3 portable FARO arms and 1 ROMER arm with 1.6m scope. All capable of 3D inspections, CAD comparison, dimensional analysis, reverse engineering and more. We also offer laser tracker services with access to Faro & Leica units with operator on request.

.svg)